Monorail Guidance Systems Things To Know Before You Get This

Wiki Article

Not known Details About Monorail Guidance Systems

Table of ContentsThe 30-Second Trick For Monorail Guidance SystemsMonorail Guidance Systems for DummiesExamine This Report on Monorail Guidance SystemsSome Known Factual Statements About Monorail Guidance Systems An Unbiased View of Monorail Guidance SystemsThe Monorail Guidance Systems PDFsThe Single Strategy To Use For Monorail Guidance Systems

This arrangement results in more decreased vehicle weight, lowered rolling resistance along with decreased tire wear in contours compared to various other dual axle bogie arrangements. Single axle bogie radially straightened in curves Producing a comfortable as well as excellent inside is an essential component of drawing travelers to any transportation system.You recognize what lifting and also product handling needs to take place in the production processes within your center. There might be special methods you intend to move an element or brand-new ways you desire to hold the component as it relocates to boost your setting up processes - Monorail guidance systems. There is no person far better than you and also your workforce understanding the positives and also negatives of the procedures you presently perform.

Workstation cranes can produce maximized setting up and manufacturing areas, retool an underused location of your manufacturing center, and add lifting as well as product handling capacities to buildings without robust superstructures. Jib cranes are discovered in virtually every sector. These cranes can be wall mounted or pillar installed, enabling raising within an area up to 360 degrees.

A Biased View of Monorail Guidance Systems

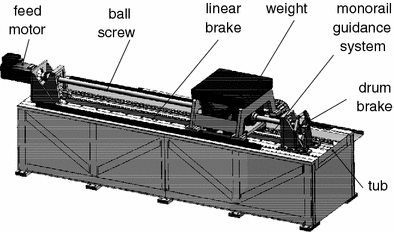

These dimensions guarantee your system offers you the correct quantity of area to work within the area and lift and action products. Elevation under the light beam for your encased rail crane or monorail guarantees that training as well as relocating procedure can be accomplished in between the bridge and also floor on a ceiling placed system. Monorail guidance systems.

In enhancement to the geographical electric needs, there are various means to supply trusted power within the crane or monorail system. Demag KBK track can be equipped with an integrated conductor line, potentially getting rid of the requirement for adorning. Festooning is a versatile option for electric and also pressed air powered applications.

4 Simple Techniques For Monorail Guidance Systems

Offered as electrical or pneumatically-driven balancers, both permit a driver to drift the load as well as maneuver it right into area with 2 hands on the tons. Demag supplies the DCBS Electric Balancer. This balancer is based off our DC chain hoist product, so it is a chain balancer with settings to meet your demands.Numerous variables can dictate whether you are called for to utilize one or the other, for circumstances weight of the tons or the travel path. Manual push trolleys are appropriate for specific applications and require to be ergonomic to maintain your labor force risk-free. Electric carts have a travel drive affixed that moves the tons.

Collect some expertise on the arrangements and also tools around that might fit your needs. Be gotten ready for your conversation with your Demag Dealer expert.

Some Known Factual Statements About Monorail Guidance Systems

New estimation software application for monorail guidance systems is now offered, which aids distributors as well as finish customers to minimise growth times for brand-new machine constructs. The software program is free-of-charge and is completely readily available via the Internet. Direct website link Easy, Option is the most up to date software program component to be launched by the Schaeffler Team for its popular moving bearing calculation software application Bearinx.

Precise computations for the interior tons distribution in the bearing are carried out, including get in touch with pressure with the actual rolling element profile and various pre-load classes. This enables individuals to minimise development times for brand-new equipment constructs. The estimation device utilizes special software application algorithms in order to mimic direct rolling bearings.

The documented calculation outcome can after that be outcome as a PDF data. Other bearing calculation tools on the market normally utilize a lot more streamlined computation methods. Displacement, tilting and also the factor to consider of stiff or elastic guideways and carriages are commonly ignored. The inner tons circulation in the bearing, which is definitive for fatigue life, is often approximated by the software.

Getting The Monorail Guidance Systems To Work

As the growth and also manufacture of high top quality, precision bearings, there is a solid focus within the business on rolling bearing design and also engineering assistance. The Schaeffler Group itself has actually successfully utilized choice as well as calculation software program programmes for greater than 30 years. Instances consist of Bearinx and medias, the company's electronic product catalogue.uk@schaeffler. com for a free copy of magazine LES.

This simple solution boosts facility productivity as well as safety and security and is perhaps the very best option for linear overhanging material handling. The crane is a totally fixed structure with the exemption of the trolley/hoist that travels on the rail (or beam of light). Curved Monorail Crane Monorail Going Here systems are extremely versatile to fit the needs of any type of center.

Some Ideas on Monorail Guidance Systems You Should Know

The style of the monorail system creates a basic centreline of traveling for production-line settings. This is essential to their performance and also in lowering security risks. It means that the course of traveling is always predictable making it less complicated to take care of the transport of products within a hectic production location.Mounting a monorail crane will result in reduced headroom. This is because of the engineering needed to support the monorail system.

Unknown Facts About Monorail Guidance Systems

If the above beams sustaining the ceiling in your building structure appropriate, a ceiling-mounted monorail system will work without influencing ground operations in any way. This makes browse around here it arguably the most functional solution for moving materials in any kind of production area. A column-mounted (or free standing) monorail crane is suited to lengthy expanses without an existing framework for support.Report this wiki page